More than ever, now is the time to ensure that your methods of working involve no more effort than is necessary to properly deliver your service, and that it is wholly focused on giving the customer value. There is no room for waste in the organisation. Wasteful activity sucks time out of the day and adds cost.

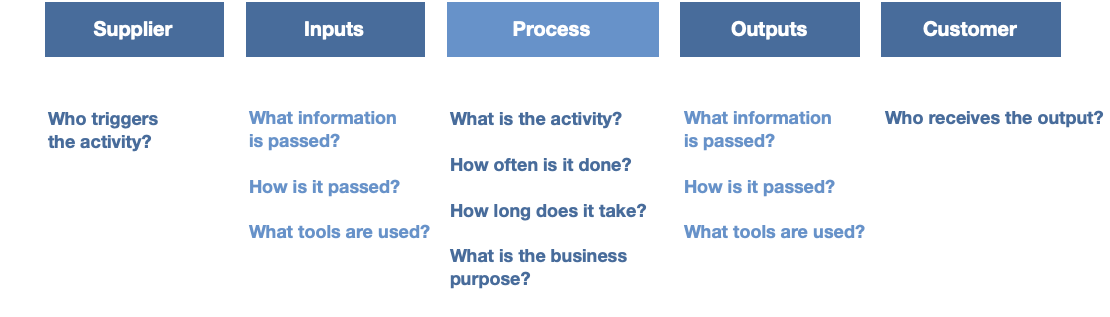

In your internal value-chain, effective working practice means that each team knows where it gets its inputs and in what format, performs the activity and then gives its output to its customer. All of these consecutive operations role up to delivering the product - and its value - to the customer.

Doing things right

Do the right thing and do the thing right.

Strategic thinking is doing the right thing for the organisation, its staff and, more widely, society.

Doing things right is about taking appropriate steps in order to achieve the required objective, both at a company level and for an individual to do the task they have been given in the proper manner. It is about executing the strategy.

It's about performing the activities within the process step of the SIPOC above.

We explore setting strategy in another post, but let's assume that the imperative is to tighten up what your people do now.

Who does what activity?

When considering what to streamline, let's think about how we come to do the activities we do. Irrespective of terminology, steps, tasks, operations, actions, and processes are all activities intended to produce some specified result.

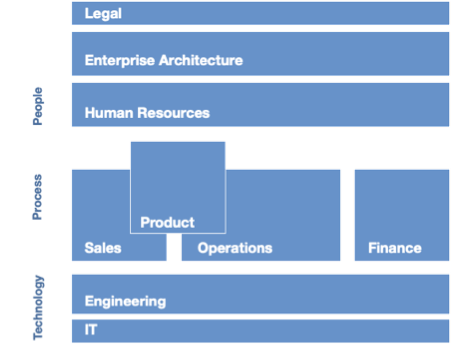

Consider a typical service organisation with functions such as:

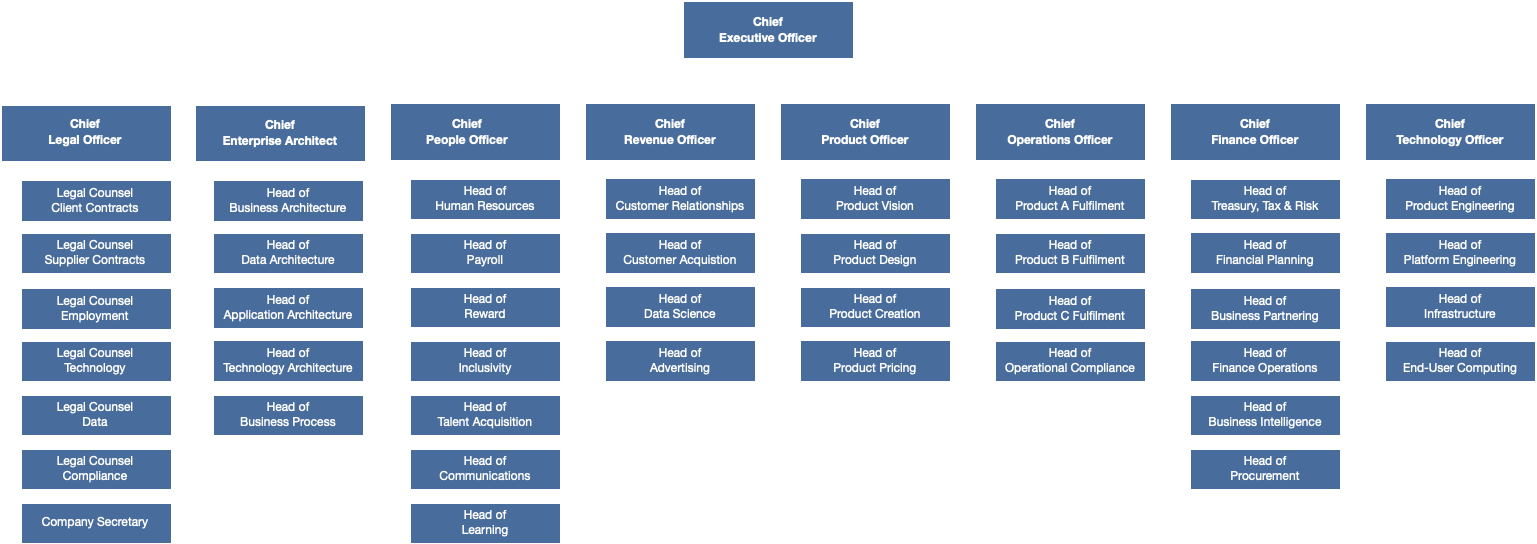

and an associated organisational structure such as:

This functional structure is a series of vertical views. People who possess specialised skills relevant to that functional area tend to end up in reporting relationshops of hierarchical authority, sometimes referred to as 'silos'.

In a functional or vertically focused organisation, if processes are documented, they tend to be the processes that the function's CxO is responsible for, or those portions of cross-functional processes found within their functional areas. Leaders direct managers and staff along departmental lines organised around task responsibilities that allow them to deliver their accountabilities.

It is often the case that no one individual is accountable for processes that cross functional boundaries. That is a prime cause of waste, and consequently corporate-wide process performance suffers.

In contrast, the process view is a horizontal view; it is concerned with flows across the organisation, with cross-functional skills all contributing the end-outcome - value for the customer. The biggest improvement you make is to reorganise business operations around delivering value to the customer. Please read on.

What to do now

Time is of the essence, so don't aim for perfection - use the 80:20 rule to get the most value you can, as soon as you can. Start by working your way through the 10 steps to streamline operations, set out below.

1. Reorganise around delivering value to the customer

You need a clear view of the cross-functional processes that your company performs. Many problems lay hidden in broken business processes and the gaps created by disconnected boundaries across vertical silos, or unclear responsibilities of roles.

Customer value, however, derives from the more natural horizontal relationships that exist between jobs, functions, and departments. Work flows horizontally across organizational boundaries from department-to-department, function-to-function, and job-to-job, in an internal value-chain.

We know that two-thirds or more of all streamling opportunities relate to broken business processes as a result of organisational silos, and the understandable human alignment to the person in charge of pay and rations - the head of that silo.

A good start would be to understand the hand-offs between teams - ie the high-level interactions between your corporate silos. At the same time, assign a crack team to capture the activities that actually people perform right now. Use the SIPOC structure, as outlined earlier in this post. Once you have that basic understanding, ask the question of if the activity is adding to the value-chain, or should be done differently, or not at all.

Action: Review Exec accountabilites. Rethink responsibilities in terms of business process and flow of work.

Action: Review reporting relationships, basing them on hand-offs makes sense.

While customer value is delivered through the execution of work, leadership rarely considers workflow when constructing the organisation chart. We discuss alternate organisational structures in our post on Leadership Tensions.

2. Streamline procedures

We observe that most work inefficiencies come from checks, reviews, and approvals due to unclear deliverables and a resulting lack of trust in decision-making. Often one deliverable relies on the production of another deliverable, so the problem compounds.

Leaders see an additional review as the answer to errors and quality deficiencies, while in actuality reviews often create a wasteful and less reliable process. This type of inefficiency is a good place to start your streamlining.

Action: Implement a clear statement - ideally in the Standard Operating Procedure - of how the deliverable will be ajudged complete. If it's a review, then criteria must be clearly stated.

3. Specify deliverables

In its simplest form, work is the execution of activities that result in outputs (deliverables) that form outcomes (products and services) to a customer (external or internal).

Our experience has shown us time and again that people focus on the activity, not the output. "I've been really busy this week". This is often because the output - the deliverables - lack clarity, specification and purpose. The staff member does that activity because they've always done it, and there is wide variation in how the same activity will result in the same deliverable - by an individual or across a team. This lack of specification is a major root cause of work flow impediments.

Action: Set out a simple specification of the deliverable, and how it will be peer checked to be 'fit for purpose'.

4. Revisit responsibilities

Many organisations have people in post who have clear responsibility for an outcome. But many don't... Or think that they do, but actually, someone else has an over-lapping claim. As organisations grow or flex as they stay relevant in a changing market then another role is created.

Job Descriptions tend to be written by the hiring reporting line. Sometimes they are stored by HR, which is helpful, but of limited use unless referenced when the Role Description is created when the end-to-end process flow is documented. Somewhere along the way, leaders have forgotten to match accountability with work.

Action: Each business process should have one establishment headcount position responsible and accountable for it performance, set by the Level 2 Process Owner (see table at the end of this post)

5. Find improvement opportunities

It's not hard to find out what needs improving. Just ask the people who do the job, and they will give you a fine list. Every individual will give you 10s of things that they are not happy with. Across a typical end-to-end business system you will find 100s of matters for investigation.

Management information will also be a rich source of improvement opportunity. Run the numbers and see what challenges the organisation is facing. If you've got a Customer Complaints call centre, or a Customer Networks team out there in social media land, you will have a steady list of matters to deal with. We talk about Root Cause Analysis in another post.

Action: Systematically talk to those who do the job about what doesn't work, ort could be improved.

Action: Have a look at what your company data is telling you. Apply Root Cause Analysis to reveal what needs to be changed.

6. Match resources

Do you have the right people to do each activity, have they got the tooling they need to make them effective? Is their work environment conducive to being happy and productive? It is surprisingly easy to overlook these points, with human nature making us reluctant to make a fuss. But think resource capacities matched to work requirements as as matter of efficiency and productivity. A newer skill and a new chair can work wonders for a team member. A new PC which starts up in seconds rather than taking 10 minutes will greatly please another. A system upgrade that avoids the need to stop, switch to excel, then re-paste in an updated variable with delight the whole team.

Action: Take a check on trainng, working environment, newness of PCs and system updates.

Given that we are cutting costs, an experienced hand has methods of achieving the above, and still delivering an overall saving.

7. Centralise data management

How many times does data get passed from team to team in your internal value stream? And not only passed, but re-typed? More than once? This is a hugely wasteful practice, in terms and time and frustration, but it also introduces multiple points of possible error. Inaccurate or insufficient data limits your team's ability to do the job, and opens up your company to customer complaint and possible non-compliance.

Further data is typically owned and stored across the organisation and is essentially uncontrolled. Data is the cause of the majority of regulatory complaints and can result in significant fines.

Action: It is essential to find out exactly what data for organisation has. Start by recording the existance, location and content of every dataset, either in a data centre or stored in the Cloud. Understand the number of records in every dataset, if they contain any personally identifiable information or credit card number, the age with respect to data retention laws in applicable jurisdictions and any contractual data segregation demands.

Action: Appoint Data Stewards from the relevant business area that uses this data.

Action: Plan for master data management, so that the same data is not replicated or kept in an uncontrolled manner.

Given that we are cutting costs, an experienced hand will know that holding the data in one place, securely, offers significant saving in storage costs. with the right controls it also lowers the cost of compliance, and mitigates against regulator fines.

8. Decentralize knowledge management

We've noted that data is typically spread across an organisation and your aim must be to centralise it. The reverse is true of knowledge. Too often it is held centrally and is very difficult to access, let alone update.

Knowledge must flow freely in an organization to get the best value from people collectively with “good ideas floating to the top” and growing the organisation for the long term. Social knowledge management promotes engagement instead of control, which can be a challenge to some Leaders. We discuss the need to move to a staff engagement paradigm in Turning your company Digital. Knowledge is the corporate memory and represents valuable intellectual property. It should be owned by and distributed to those who know it, need it, use it and update it.

Action: Implement a Social Knowledge Management tool.

Given that we are cutting costs, an experienced hand will know that the modest cost of a tool, will be more than repaid in time no longer lost looking for information, an in giving your millennial staff a tool that works the way they think, for greater productivity.

9. Fix what’s broken.

Sometimes streamlining operations is about facing up to what doesn't work and changing it. While implementing a revised process is usually simple, the trick is to propose a solution that solves more than one problem at once.

Action: There will be a list on someone's wall; find it and categorise and prioritise the opportunities to fix.

Given that we are cutting costs, an experienced hand will know what's worth fixing and what should be discarded. Any expenditure should be met by savings of at least twice the value.

10. Measure what matters

In our experience, the majority of measurements and reports are either meaningless, igored or both. Industry KPIs aren't necessarily helpful either. Your organisation needs to understand the purpose of each of its business systems / products, and focus on measuring the meaningul performance of each.

Action: Express a goal and determine what measure will tell you if the goal has been achieved, or not.

Finally... the management of change is essential to successful improvement. Change control is essential to the management of change. Governance must be established to manage the performance of the key business processes as well as the initiatives to change them.

Lean Management

Before we close this line of thought, its worth mentioning that Lean management is an approach to managing an organisation that supports the concept of continuous improvement; a long-term approach to work that systematically seeks to achieve small, incremental changes in processes in order to improve efficiency and quality.

Lean, in engineering terms, can be defined as a production process that has no waste; in a service business, it is an internal value chain that has no waste. Any activities that do not contribute to the value of your product are waste.

There are 8 Principles of Lean:

- Be customer driven – do not do anything until there is customer demand.

- Maximise flow – once something has started, finish it.

- Identify and eliminate wastes – materials, time and resources.

- Declare war on variation – variation creates uncertainty, in turn causing waste.

- Organise people around wanted outcomes – each person is accountable for delivery of their job.

- Equip people – with the skills needed to be successful at their roles.

- Implement measures and controls – warning indicators to help adapt to changes quickly.

- Deliver a clear message – to communicate ideals.

The 8 Wastes of Lean is an industry standard for streamlining operations:

Lean is as much a philosophy as a framework for action. It is an invaluable approach to streamlining operations at any time, irrespective of the current trading trauma.

Caution

When looking to make improvements, in your organisation you'll find adherents of starting at the top - the process view - and decomposing down, and just as many who insist that we can only accurately know exactly what we do if we start at the bottom and aggregate up. The latter approach identifies how the work is currently done rather than the sometimes theoretical process view of how it should be done, so taking the bottom-up approach is what you need to make rapid improvements to streamline operations.

The ideal situation is to have to hand a top-down taxonomy based on the strategic view, and then, as you capture the tasks and steps that are performed at individual / team leader level, map them back onto the taxonomy. This way, you'll have an accurate resource for when the Process Owner can assign resources to the end-to-end process view.

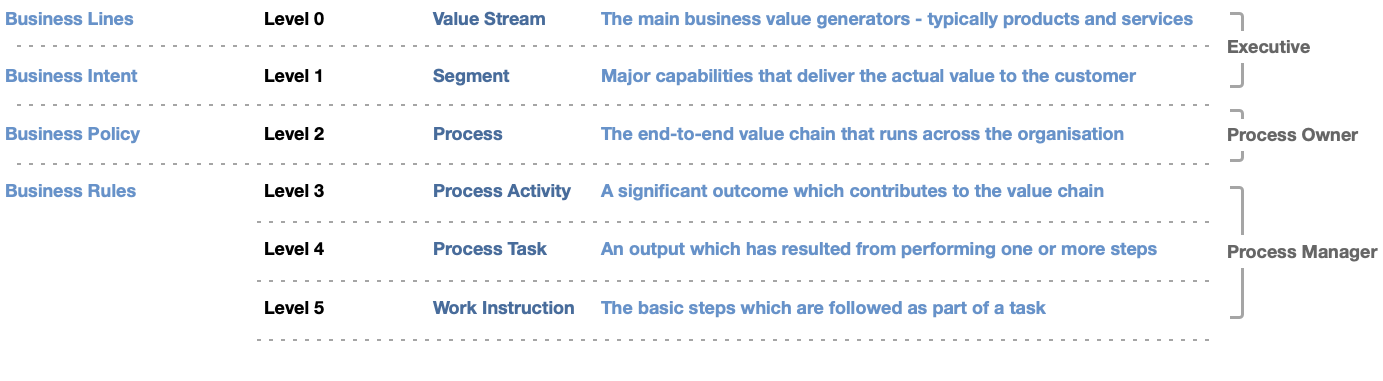

A typical process taxonomy structure:

It's worth noting that in the process taxonomy:

- Levels 0 to 2 should be the subject of Enterprise Architecture enquiry.

- Levels 3 to 4 are where most business process redesign will take place.

- Levels 4 to 5 can benefit from being automated.

When the pressure is on to streamline operations, you don't have the luxury of mapping out the ideal process, so put the effort into Levels 4 & 5.